Alphasonics

Founded in Liverpool, England in 1983, Alphasonics has developed a worldwide reputation for innovation and technical excellence. Their broad product line ranges from cost-effective tabletop ultrasonic anilox roll cleaners to console systems for wide web applications. Alphasonic also offers two outstanding systems for cleaning Flexo printing plates, the compact PW Series and the high volume PC Series.

When selecting an ultrasonic cleaning system, three factors should be considered. FREQUENCY, POWER and FREQUENCY SWEEP are what go into producing an anilox cleaning system that will enable the user to clean his rolls effectively and safely. For additional information on these three critical features, Click here.

The complete Alphasonics equipment brochure is available for easy download. Click here.

Click here for a downloadable PDF Data Sheet

Conversource stocks all Alphaclean chemicals for immediate shipment to any U.S. mainland locations.

Alphaclean 1

The standard chemistry for removal of water-based and solvent-based inks.

Alphaclean 3

The enhanced Alphaclean 3 is the choice for removing standard inks plus UV inks.

Alphaclean 7

Powdered neutralizer often required before disposal of spent liquid chemicals.

Melanie Anilox Cleaning System Available in either single or dual frequency, the benchtop Melanie system incorporates advanced Alphasound technology at an affordable price. Despite its small appearance and price tag; it has the potential to clean up to six rolls simultaneously with a cleaning ability usually found in high specification systems. Features at a glance:

|

|

|

Mia Anilox Cleaning System The Mia series incorporates the features of a high specification unit with the compact nature of a benchtop model. This system brings the most sophisticated cleaning technology to the benches of smaller printers, giving them an advantage usually reserved for only the largest print houses.

|

|

|

Miranda Anilox Cleaning System These floor standing models can be found in pressrooms worldwide. The Miranda series utilise cutting edge technology and are ideal for rolls of low to mid range screen counts. They are manufactured to the strictest specifications to ensure the highest standards available in the flexo and gravure industries.

|

|

|

Megan Anilox Cleaning System The Megan series of floor standing models brings together the latest technology that has come as a result of years of Alphasound research. With a variety of easy to use cleaning options that can be selected using the simple menu system and an outstanding range of features, these systems are the absolute pinnacle of ultrasonic cleaning technology. What’s more, these systems revert to it’s most gentle setting at the end of the cycle and incorporate ‘temperature fall back’, giving payback potential through reducing energy costs.

|

|

|

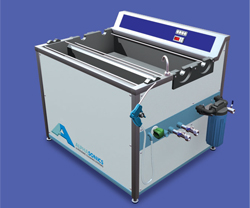

PW Series Flexo Plate Cleaning System This compact yet highly impressive lower cost system eliminates the problems associated with the cleaning and potential damage of high line flexo plates. The PW series cleans to supreme standards and now incorporates an air blade system which will dry the plate with absolutely no contact at any stage.

|

|

|

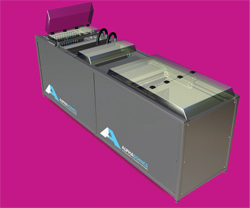

PC Series Flexo Plate Cleaning System The Alphasonics PC Series breaks the mould for flexo plate cleaning systems through the use of sophisticated technology and unmatched excellence in engineering standards. This totally automatic unit requires zero skill level and again requires no contact with the image area of the plate in the cleaning or drying processes. These revolutionary systems are safe and effective and remove any margin for error.

|

|

|